Vent Trimmer - Truck Tires

Features

- No Pre-Sorting

- Bead-to-Bead Trimming

- Fully Automatic

- Dual Knife Arrangement

- 4 Tires per Minute

- Up to 60″ Tire OD

Description

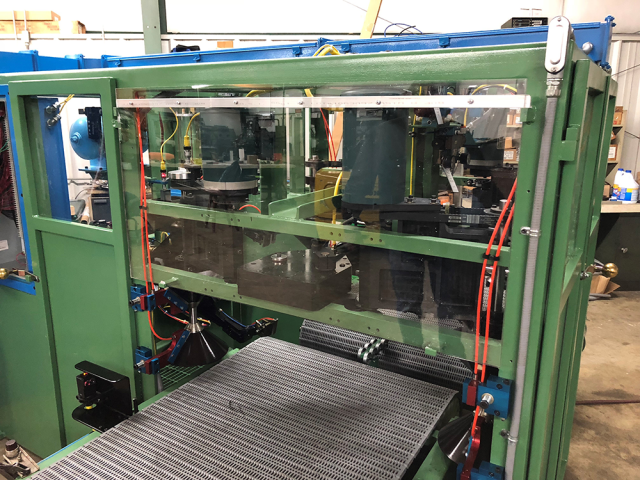

The Spadone Vent Trimmer handles passenger and truck tires up to 60” OD. Different size tires can be fed randomly to the machine, which senses the dimensions of the tire and adjusts the variables required without interrupting productivity. The machine operates unattended for maximum production capability.

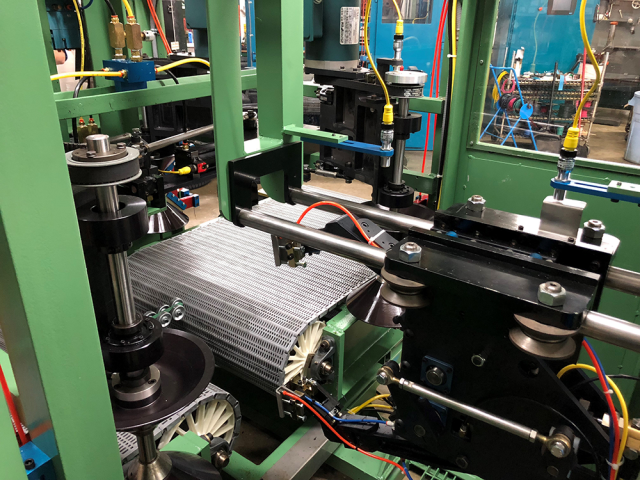

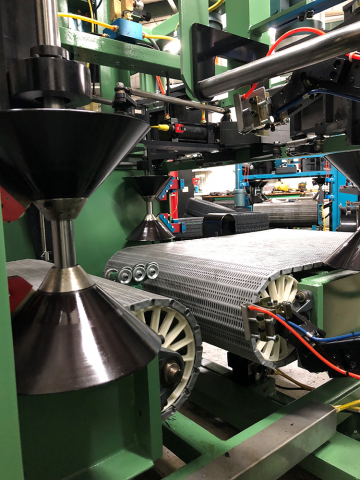

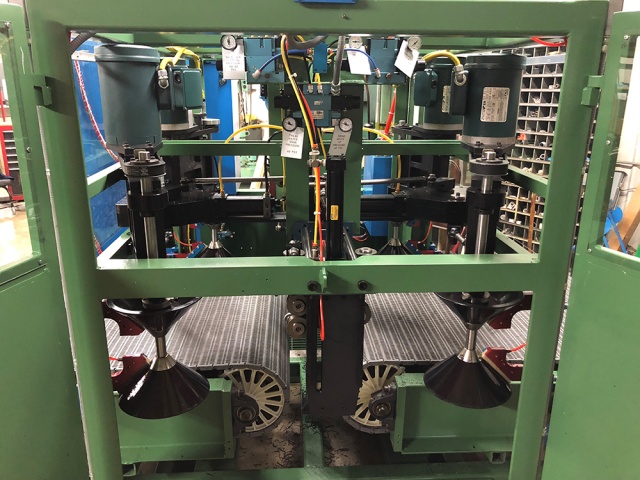

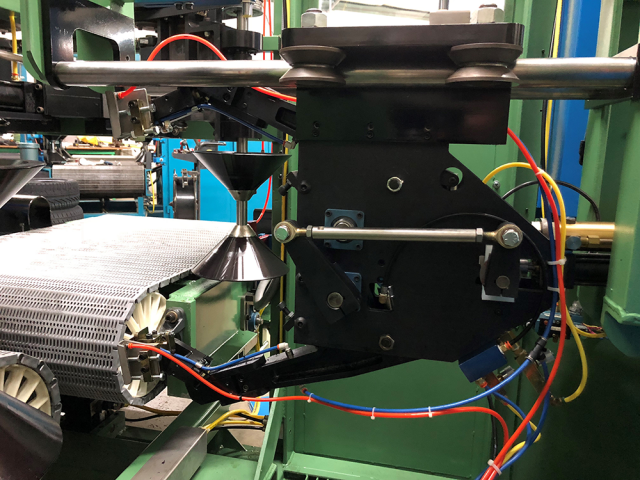

Tires are conveyed to the center of the trim station where 4 rotating cone-shaped spindles swing in to support and spin the tire. Once the tire is supported, both the infeed and outfeed conveyors drop 1 1/2″ to allow the tire to spin freely. Prior to spinning, a small amount of lubricant is sprayed onto the spindles and knives to prevent friction between the tire and the machine. When the trim cycle is complete the conveyors are raised to eject the tire.

During the trim operation, a total of 3 knives press against the spinning tire to assure close trim and high production. A single knife concentrates on the tread and a pair of hinged knives trim the sidewalls down to the bead (if desired). The machine is equipped with knives that are economical to use and easy to install.

The Spadone Vent Trimmer may be customized to meet specific requirements. Spadone is a pioneer with over 100 years of experience in the manufacture of equipment and specialty production machines for the rubber and tire industry.

Specifications

| Tire O.D. | 24” minimum

60” maximum |

| Tire Width | 3″ minimum

12″ maximum |

| Note: Above dimensions can be modified to customer specifications | |

| Trim Cycle Rate | 4 tires per minute |

| Trim Accuracy | 1/32” to 1/16” |

| Knives | Commercially available |

| Type of Lubricant | Pro-Tire Lube |

| Lubricant Consumption Rate | 1 quart per day |