Low Angle Bias Cutters

Features

- Fully Automatic

- Cut Angles from 12° to 90°

- Cut Steel Cord and Textile Fabric

- Precise Servo-Driven Conveyor

- Production of 20+ CPM

- Fabric Compensator System with Edge Guiding

- Automatic Splicing

- Available with Let-Offs and Wind-Ups

Description

The Spadone Low Angle Bias Cutter is designed to cut ply stock, including steel cord, at angles of 12° to 90° from full width rolls of fabric. The width of ply is controlled by an encoder riding directly on the fabric and the cutter conveyor is powered by an A.C. Servo drive. The fabric is clamped to the belt during the cutting operation.

The cutter beam is supported from an overhead ring with a readily visible angle scale and indicator. The cut angle is set by swinging the beam to the desired angle and once set, the beam is held in place by air clamps.

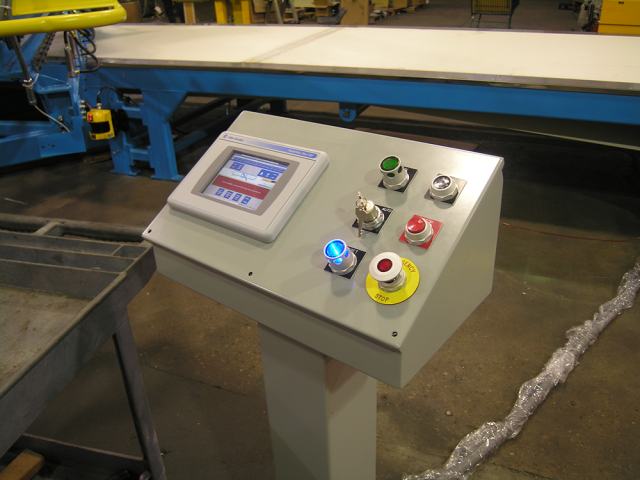

The standard conveyor is 30′ long but can be extended to provide room for supplemental operations. The control system is furnished with the latest Allen Bradley PLC. Available with let-offs and wind-ups, this accurate, versatile machine can be tailored to meet your exact bias cutting needs.

Optional features such as spreader rolls, safety chucks and pricker rolls can also be furnished to your specification.

The Low Angle Bias Cutter may be customized to meet specific requirements. Spadone is a pioneer with over 100 years of experience in the manufacture of bias cutting systems and specialty production machines for the rubber and tire industry.

Specifications

| Fabric Width | 59” |

| Cut Angle | 12° to 90° |

| Cute Widths | 4” to 99” wide at 90°

3” to 27” wide at 16° |

| Knife Carriage Travel | Adjustable from 75” to 258” |

| Cute Width Accuracy | +/- .060” or better |

| Cut Angle Accuracy | +/- ½° |

| Conveyor Drive | Servo motor – peak torque 400 lb.-inches |

| Knife Motor | ½ HP A.C. |

| Knife | 3 ¾“ diameter for standard fabric

5” diameter for steel cord 7,000 RPM |