White Sidewall Buffer Upgrade Kits

Features

- OEM Engineered Enhancements

- Reduces Maintenance and Downtime

- Extends the Life of Legacy Equipment

- Increases Production and Quality

Description

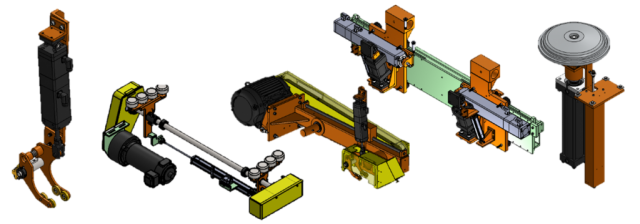

Spadone’s White Sidewall Buffers and Grinders have remained a fixture in tire manufacturing plants around the world. We offer several simple conversions and rebuilds that improve performance and reduce maintenance, as well as machine add-ons that will improve productivity and efficiency. Contact us with the serial number of the machine to see if your Spadone machine can benefit from the upgrade kits or factory rebuilds listed below.

Controls System Rebuild

New machine control enclosures. All control components assembled and wired in Hoffman enclosures ready for integration to the machine. Kinetix 350 Servo drives (4) axis, all motor controls for AC motors including Powerflex drives. Includes all Servo cables, junction boxes, HMI, pushbutton enclosures and operator station. Current PLC Program. Does not include any communication provision for upstream equipment. Provided for stand-alone automatic tire processing.

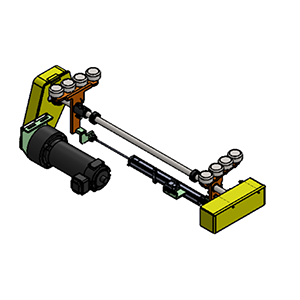

Automatic Depth Guide Assemblies

Current mechanical assemblies of (2) wheel depth guides. Includes Allen Bradley Linear Servo motors and all hardware for mounting, both fine and coarse sides.

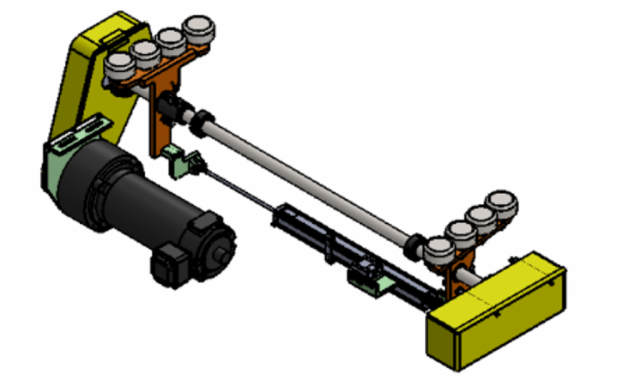

Programmable Tire Centering Assembly

Motor driven assembly with lh/rh ball screw and centering rollers. Provided with LDT feedback transducer. Programmable center positioning for infeed

Spindle Drive Assemblies

Grind Arm Assemblies includes new grind arms and all supporting structure. Does not include grind stone mandrel housing assemblies. Includes Hydraulic actuators and position feedback LDT’s. Both fine and course sides.

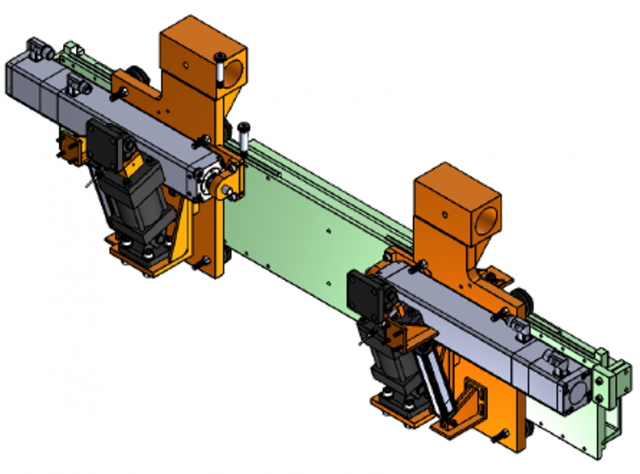

Support Plate and Drive Assemblies

Frame mounted support plate with vee guide wheels and track and linear AB servo motors complete for radial positioning of the grind arms. Both fine and coarse sides.

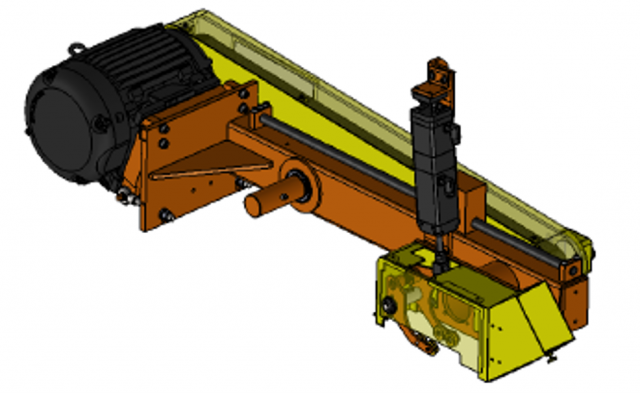

Programmable Bead Spread Assembly

Mechanical assembly of lower chuck positioning system. Includes hydraulic cylinder and all supporting structure, LDT position feedback transducer, lower chuck spindle assembly (chuck not included). Includes standalone 15 hp Hydraulic power supply and all hoses and fittings complete with proportional valve for control.