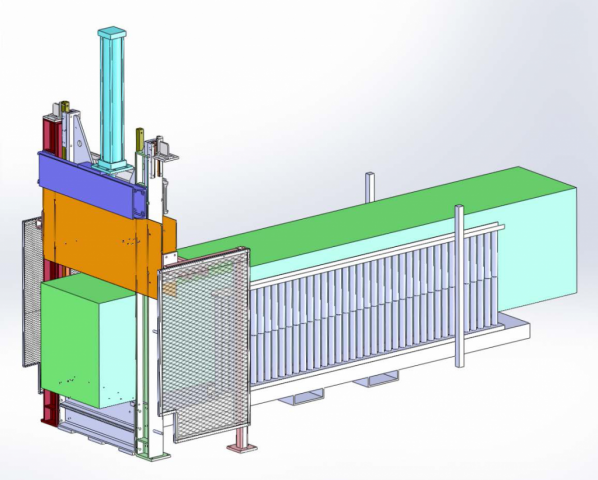

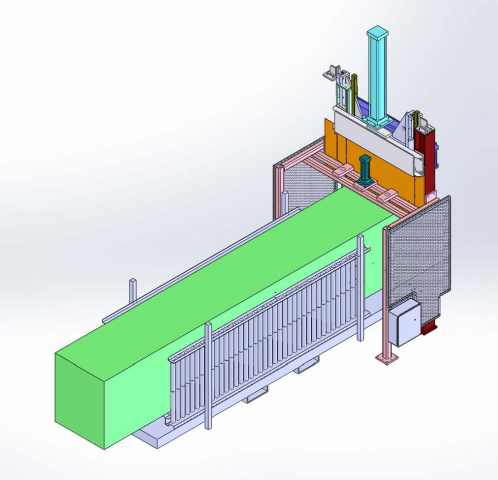

Custom Guillotine and Bale Cutter

Features

- Hydraulic or Pneumatic

- Designed to customer specifications

- Cutting widths in excess of 72”

- Custom designed infeed and outfeed conveyors and chutes

Description

Spadone’s Guillotines and Bale Cutters are designed for the most demanding applications. For over 100 years, Spadone has manufactured rugged and dependable machines for many industrial applications. Spadone’s Guillotines and Bale Cutters are used to cut tough, dense materials for which other cutting methods are inappropriate. Spadone offers custom designed equipment, enclosures, infeed and outfeed conveyors and chutes for every application and material with cutting widths in excess of 72” and over 125,000 lbs. of cutting force.

Designed to yield a low maintenance, low cost, long lasting impact to any cutting procedure

- Standardized cutter materials and weld patterns that have been developed over 100 years of material cutting industry service allow for consistent overall dimension tolerances and repeatable cuts on the hardest natural or synthetic rubbers and plastics.

- Fully welded cutter frames with casted sub-components (where necessary) ensure long equipment lifespan thereby minimizing replacement costs and increasing utilization. Any consumable components are designed for easy replacement and quick procurement.

- Spadone’s vast amount of industry experience and product testing have perfected the design of pneumatic and hydraulic cutters to accommodate a maximum cut width of 72″ and a maximum cutting height of 48″. We have engineered a great deal of flexibility into our cutters for simple integration into preexisting systems as well as the capability to suit any customer need or request.

Designed to effortlessly perform cutting processes and integrate into any customer operation

- Spadone Cutters are available options for connection both static and electrically powered in-feed and out-feed conveyance operations which can be vital for cutting material at constant or variable index lengths.

- Standard design packages supply a two-push button system using anti-tie down logic which requires both buttons be depressed simultaneously for operation thereby removing any chances for operator pinch points. Signal actuated systems are also available to connect cutter operations with customer line controls.

- Along with the anti-tie down logic, all cutters are supplied standard with machine guarding for operator safety. Machine guarding is framed in steel with clear paneling; or can be customized to the customer’s specifications and company guidelines. Additional safety parameters such as light curtains and pull cords are available upon request.

- Cutter equipment placement allows for a small, compact footprint. Hydraulic units can be installed underneath the cutter thus reducing a need for locating components outside of the cutter floor space.

- All bale cutters are delivered turnkey with mechanical, electrical, and pneumatic drawings and bill of materials for simple installation on field and to allow quick procurement of any spare or replacement parts.