White Sidewall Buffer

Features

- Fully Automatic or Manual Set-up

- Quick Chuck and Grinding Wheel Change

- Two Step Grinding: Coarse and Fine

- Latest Servo Technology

- High production capability

- Rugged and Dependable

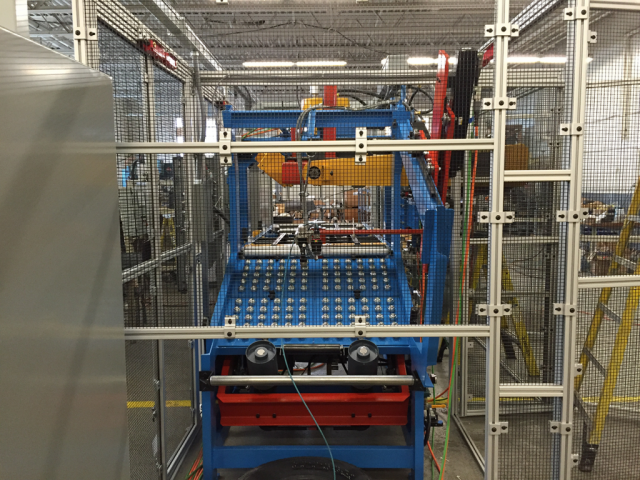

- Guarded for Operator Safety

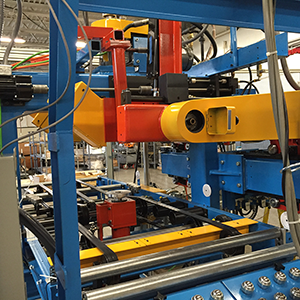

Description

Two models of the Spadone White Sidewall Grinding Machine are available: manual set-up and automatic set-up with memory. The set-up functions include:

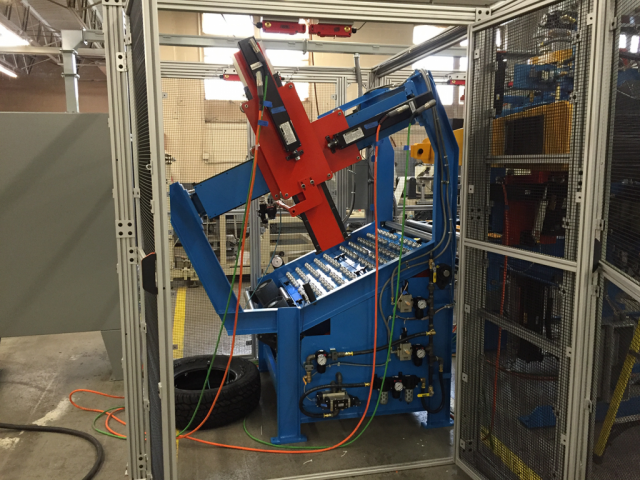

- Centering the tire on the conveyor

- Positioning the tire over the lower chuck

- Radial adjustment of the grinding wheels

- Positioning of the lower chuck bead spread to control the tire surface presented to the grinding wheels

- Depth guide adjustment (automatic optional)

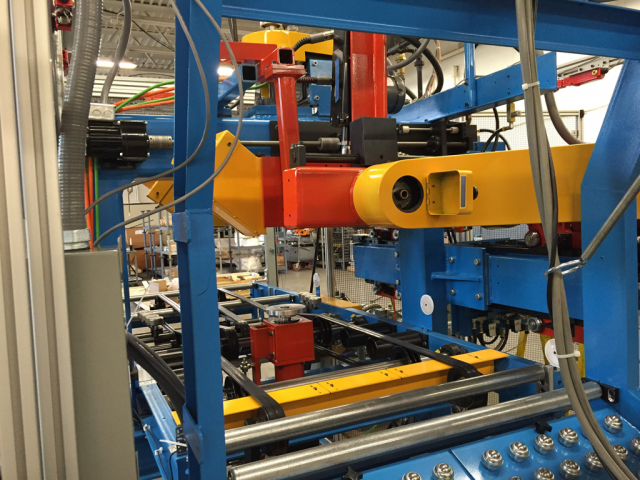

Both grinding wheel assemblies are mounted on the same side of the machine at 90° to the direction of the tire travel leaving one side open for easy access to the tire chuck and the grinding wheels. Pressure of the grinding wheels is controlled by an adjustable weight which provides exact pressure for repeatability and conformity. No angle adjustment of the buffing wheel is required.

Backed over 100 years of experience, these machines are designed for fast, easy change of both the grinding wheels and chucks and are supplied with a programmable controller furnished to customer specification.

Specifications

| Tire O.D. | 22 ½” minimum

37 ¼” maximum |

| Grind Diameter | 16″ minimum

32″ maximum |

| Note: Above dimensions can be modified to

customer specifications |

|

| Tire Cross Section | 15″ maximum |

| Chuck Size | 15“ to 24“ |

| (Step chucks available) | |

| Grinding Wheel Speed | 5,630 RPM

(with 60 hz. service) |

| Tire Rotation Speed | 16.5 RPM

(with 60 hz. service) |

| (2) Grinding Wheel Motors | 15 H.P. each

energy efficient |

| (1) Conveyor Drive | ½ H.P. each |

| (1) Chuck Drive | ½ H.P. each |