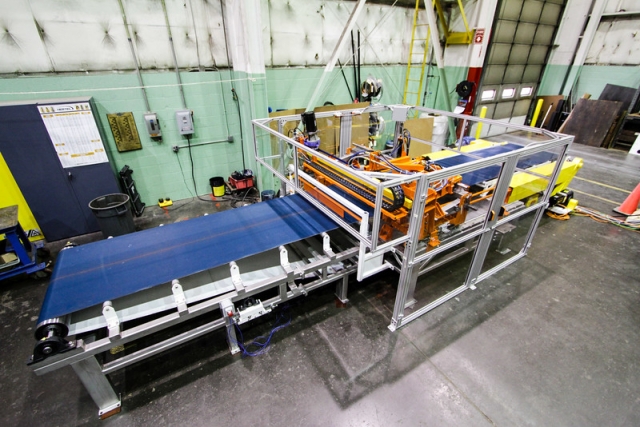

M7 Servo Tread Skiver

Features

- Fully Automatic

- Production of 26+ CPM

- Precise Three Servo Axis

- Smooth and Quiet Operation

- Close Accuracy

- Rugged and Dependable

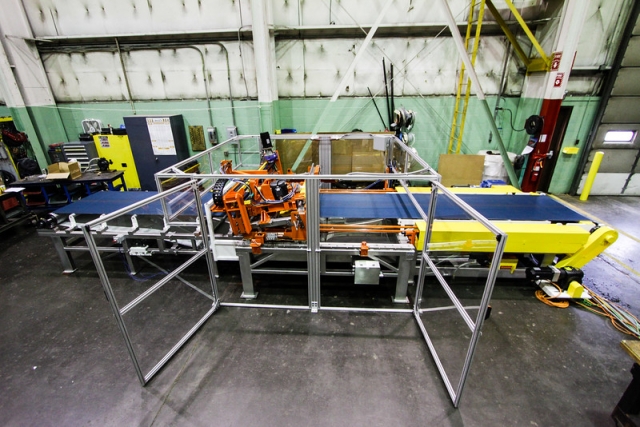

- Guarded for Operator Safety

Description

The M7 Servo Tread Skiver utilizes the latest servo technology to achieve outstanding accuracy. The cutter produces through a full range of line speeds and is capable of holding tight cutting tolerances at rates in excess of 26 cuts per minute.

There are three servo axes in the system. The first controls the speed of the conveyor while the second controls the downstream motion of the cross carriage. Together the two encoders monitor and adjust the position of the cutter carriage to the speed of the conveyor.

The cross cut carriage is also servo driven. Changing the length of knife carriage travel maximizes the production rate for varying extrusion widths. This and other operations are easily accomplished through the operator input terminal. There are no shock absorbers, no physical stops and no clutches. Performance is accurate, smooth and quiet. Maintenance is minimal.

The M7 Servo Tread Skiver meets the highest quality and production demands of today’s tire industry and represents Spadone’s continuing commitment to outstanding engineering.

Specifications

| Cycle Rate | 26 CPM+ |

| Line Speed | 135 feet per minute+ |

| Repeatability | +/- .060” or better |

| Length Control | Servo system with master scale encoder |

| Cut Length | 150” max |

| Stock Width | 36” Skiver: 32”

42” Skiver: 38” |

| Angle Adjustment Range | 15° through 30° |

| Knife Motor | 5 HP, AC, 1800 RPM, aluminum frame |

| Knife | 20” diameter, can be resharpened to 18” |

| Knife Lubrication | Water spray mist system |

| Conveyor Belt | 4 ply ribbed poly belt |

| Guarding | Complete, including floor mounted enclosure around moving carriages |

| Services Required | Electrical: adaptable to local requirements |

| Air | 80 PSI max, 1” NPT feed line |

| Water | ½” NPT feed line |